D523 Standard & Custom

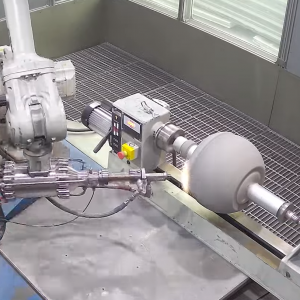

Integrate our compact low-pressure cold spray system on-site, for on-demand metal coatings and repairs.

From ballistics to barrels and anti-corrosion to induction coatings, produce high-performing parts or perform coatings and repairs on demand – while combating the most complex manufacturing challenges.

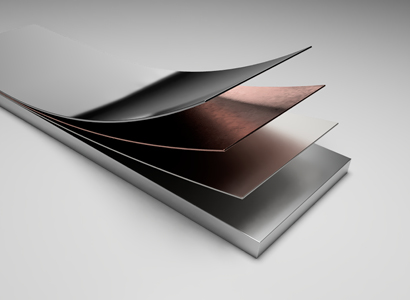

Cut costs and simplify your supply chain with our breakthrough Titomic Kinetic Fusion Additive Manufacturing (TKF AM) systems.

Engineered to provide compact capability – with rapid prototyping and manufacturing tailored to your production needs – our systems complement your existing processes to unlock limitless design possibilities like never before.

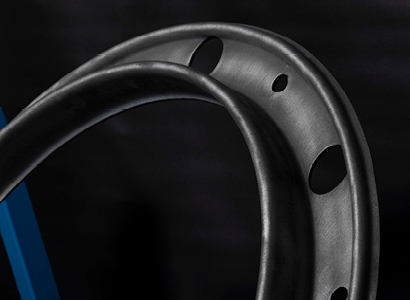

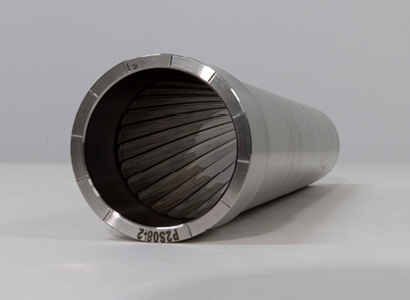

Produce large multi-metal barrels that are lighter and offer better corrosion and erosion performance than traditional techniques.

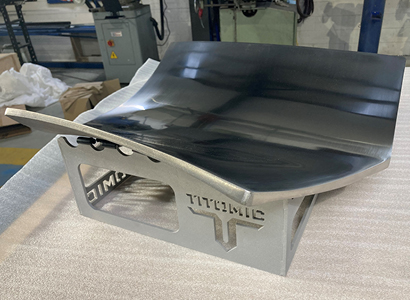

Produce larger, lightweight titanium armour at a competitive price point.

Replace complex and costly welded assemblies with single-piece structures.

Produce stronger, lighter, thinner and corrosion-resistant near-net shape faceplates – with reduced welding, assembly and lead times.

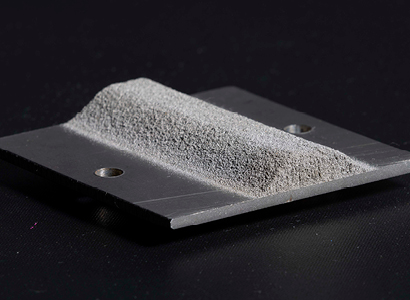

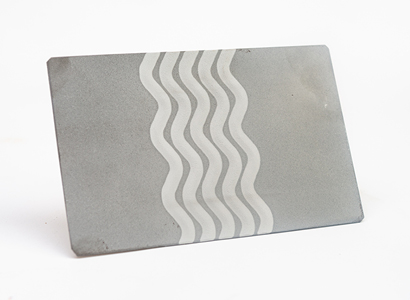

Whether you’re working with metals or temperature-sensitive materials like glass, ceramics and plastics, our fully customisable cold spray systems allow you to make rapid repairs and apply metal coatings without heat – making it possible to restore parts and create coatings with unparalleled thickness, adhesion, density, conductivity and corrosion resistance. So you can maximise your uptime, output and productivity in a world of increasingly complex challenges.

Unlock a reliable, enduring, lightweight and cost-effective alternative to prohibitively expensive radiation-hardened electronics.

Deposit hard-wearing metals such as titanium, steel, and tungsten to enhance wear resistance on existing or new parts. Hard-wearing metals can also be fused to existing, dissimilar metal parts for repair and to enhance lifespan.

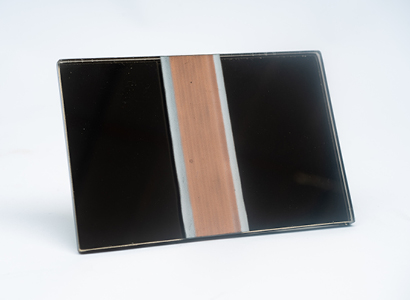

Rapidly add ferrous metals to dissimilar metal parts, to enable induction technology in cookware, manufacturing and more.

Create solar panel componentry and add hard-wearing efficiencies to wind turbine blades, as well as combine materials for electrical and thermal conductivity.

Use Titomic Kinetic Fusion to apply corrosion-resistant materials such as titanium to new or existing parts, enhancing their lifespan in corrosive environments across marine, chemical, and oil and gas applications.

Use Titomic Kinetic Fusion systems to rapidly repair metal parts, restoring them to working order in applications across aerospace, mining, defence, boilermaking and more. The D523 sprays metal in seconds, so you can restore parts in minutes.

Use Titomic Kinetic Fusion to build and incorporate electronic sensors directly into parts, providing hard-wearing, anti-corrosion, and wear-resistant analytical sensors for offshore oil and gas, subterranean piping and more.

Whatever parts or products you seek to build, coat or repair, our customisable systems make it faster, easier and more viable than ever before.

Explore our systems for additive manufacturing, coatings and repairs – or see how we can integrate a solution into your production line to solve your specific manufacturing challenges.

Integrate our compact low-pressure cold spray system on-site, for on-demand metal coatings and repairs.

Go beyond 3D printing manufacturing with faster, simpler, on-demand additive manufacturing.

Customised to your needs, the ISB unlocks the possibilities of large-scale cold spray manufacturing.

By working together, we can overcome your manufacturing challenges and build what’s next in new and novel ways.

Titomic’s Cold Spray Technology streamlines casting repair, ensuring fast, precise, and undistorted results for your high-stakes industrial components.

Learn how Titomic’s D523 low-pressure cold spray system was used to quickly repair a classic car with no heat. The no-heat process does what welding, putty, and epoxies couldn’t for 20 years. Now, this vintage race car is back on the track, ready to take its driver toward the podium.

Get in touch to see what we can achieve together.

Learn what other industry leaders have achieved with our TKF Additive Manufacturing System.