World’s first medium-pressure cold spray system

The D623 system is used in the repair and restoration of various metal parts, including engine components and moulds. It is also effective for sealing, corrosion protection, enhancing electrical conductivity, and other specialised applications. Additionally, the D623 system is suitable for applying coatings, such as electrically conductive coatings and corrosion-resistant layers. Whether you’re working with metals, glass, ceramics or plastics, the D623 system unlocks a wide variety of applications.

- Compatible with ISB-Linear system, including XY robotic system for repeatable coating and secondary manufacturing operations.

- Deposit dissimilar metals, such as aluminium onto steel, or nickel onto cast iron

- Broad range of metals available. If it is available as a powder, it could be deposited with cold spray.

Medium pressure

Features

Versatile handheld and robotised systems

Fuse dissimilar metals to create custom solutions

No excess heat, avoiding cracking and warping

Create high-performance metal coatings

Deposit layers of metal with 99% density

Reduce downtime and replacement costs

Deposit Inconel 625

Repair without the need for disassembly

Leading companies using the D623 system

Titomic has successfully introduced the D623 for University R&D and education, and aerospace MRO.

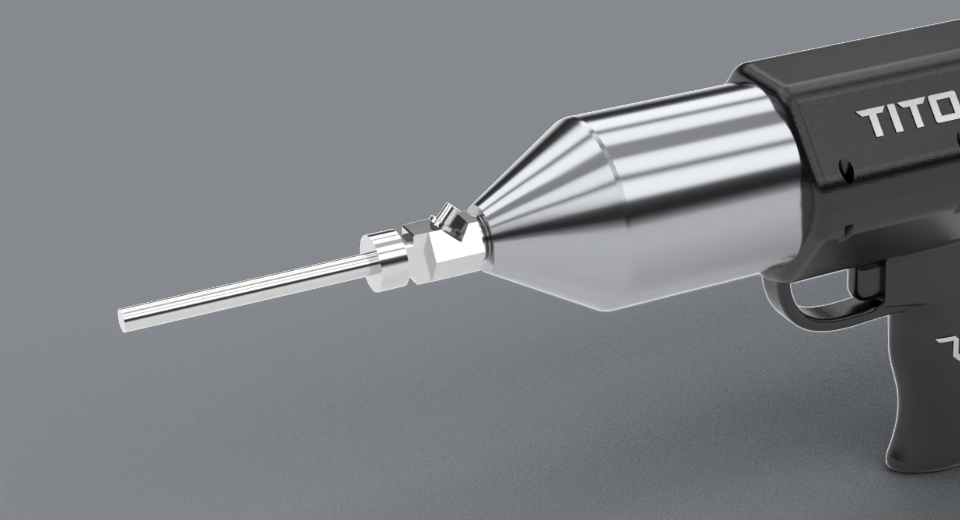

Improved nozzle design

The D623 features an enhanced, new generation deposition nozzle designed by Titomic for enhanced deposition efficiency and processing of harder metals.

System features

- Max pressure: 19 bar

- Max. temperature : 700 degrees°C

- Air flow 420 litres per minute, max pressure 19 bar

- Deposition efficiency increased by over 30%

- Power feeder: Dual 1.5 litre disk feeder (option)

- Vacuum powder injection

- 4kg spray gun – handheld or mountable to machine or robot

Specifications

| System | D523 |

| Powderfeeders (PB-45) | 2 |

| Power connection | 230V AC 50/60 Hz |

| Power | 3.3 KW |

| Temperature settings | Variable 20 – 600ºC |

| Parameter logging (temperature, pressure and flow) | Yes |

| Closed loop integration | Yes (optional) |

| Spray parameter library | Yes |

| Carrier gas: Air/N2 | Yes |

| Gas requirement | 6 bar/400L/min |

| Mix air / N2 | Yes (optional) |

| Particle velocity | -600 m/sec |

| Spray rate | -30 gr/min |

| Air/N2 pressure control/ regulating | Yes |

| Full colour HMI touchscreen | Yes |

| Bus or ethernet/IP connections | Yes |

| Recommended for industrial robot applications | Yes |

| Weight and dimensions | 43kg / 550 x 1420 x 266mm |

Looking for material data and information on cold spray performance?

See what’s possible

Book a complimentary consultation to help decide if our solutions are right for you.