Titomic’s cool contribution to SpIRIT satellite launch

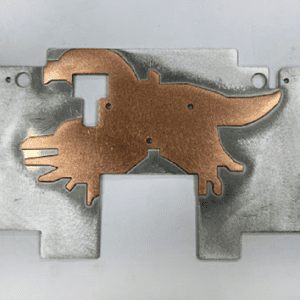

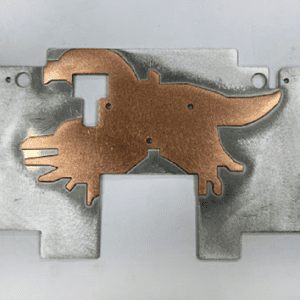

Discover how Titomic have designed a bespoke heat management system for Australia’s first scientific satellite in 20 years using cold spray.

Repairing and restoring metal components can be complex and time consuming – and the right technique can make all the difference.

But while cold spray and welding are two popular options, they each have their own benefits and limitations. So which one should you choose? This guide should help you decide.

While our article What is cold spray? covers this revolutionary method in more detail, here’s a brief snapshot:

Cold spray is a process in which metal powders are accelerated to high speeds using compressed gas, and then impacted onto a substrate. This forces the particles to bond to the substrate, forming a dense, solid coating.

Produce coatings with fine-grained microstructures and minimal porosity to enhance their mechanical properties, durability and functionality.

Use a wider variety of metal alloys (including high-temperature and reactive materials that aren’t easily melted) and open up new possibilities for restoring components previously considered to be beyond repair.

Repair corrosion and provide long-lasting protection, such as in marine applications where grit is used to blast away corrosion and apply corrosion-resistant aluminium to steel structures – without the need for disassembly.

Repair delicate or temperature-sensitive components (such as electronic devices and aerospace components) with minimal heat output, reducing the risk of thermal damage to the substrate and surrounding areas.

Repair obsolete or expensive components in hours – rather than waiting months for replacement parts.

There’s a reason why welding has been a staple of metal repair and restoration for decades. By heating metal parts until sections of them become pliable or molten, it’s easy to mould them together – as well as make joints more precise and controlled. And because welding can join metal parts of any thickness, it’s a versatile way to build a wide range of metal components.

But there’s a catch: welding a large area to repair geometry or surface imperfections can introduce significant heat. This threatens the metal’s grain structure, potentially causing warping, cracking, or heat distortion.

See how our low-pressure cold spray systems rapidly restores metal parts, to drastically reduce repair and maintenance costs.

Learn what other industry leaders have achieved with our TKF Additive Manufacturing System.

Discover how Titomic have designed a bespoke heat management system for Australia’s first scientific satellite in 20 years using cold spray.

Titomic’s cold spray technology brings new capabilities to engine refurbishment by eliminating heat damage, reducing costs, and minimising downtime.

with us today to see how you can leverage cold spray to save time and costs.