Rensselaer Polytechnic Institute (RPI) has embraced Titomic’s D523 low-pressure cold spray system to revolutionise its research and education efforts in advanced manufacturing and surface engineering. The system’s cutting-edge features, including a Human-Machine Interface (HMI) for in-situ process control and seamless integration with robotic systems, have enabled groundbreaking advancements in various fields.

Key Research Applications and Innovations

RPI researchers have utilised the D523 system in diverse projects, demonstrating its versatility and potential across multiple domains:

- Functional Metallisation on Polymers

Developing energy devices such as triboelectric nanogenerators with enhanced performance and functionality. - Multi-Material Hybrid Surfaces

Creating corrosion-resistant, wear-resistant, and antibacterial coatings that push the boundaries of material science. - Advanced Coatings for Electronics and Sensors

Engineering protective and high-performance layers for electronic components and sensor packaging. - Sustainable Repairing

Innovating eco-friendly methods to repair and restore components, reducing environmental impact.

Advancing Education and Workforce Development

The D523 system also plays a critical role in education and skill development. Beyond equipping future engineers and material scientists with cutting-edge tools for research, it serves as a valuable training platform for tradespeople in fields like automotive remanufacturing, maintenance, repair, and overhaul (MRO), and general engineering.

The system complements traditional skills in welding and machining, enabling professionals to enhance their capabilities with modern cold spray techniques.

The system’s ability to facilitate innovative research contributes to the publication of new insights into material science and metallurgy, cementing its place as a vital educational resource.

Insights from RPI’s Researcher

The system’s mobility, robotic compatibility, and automatic cleaning features also contribute to its status as an essential tool for advanced research and development. Dr Semih Akin, a leading researcher at RPI, emphasises the transformative potential of the D523 system:

"Cold spray additive manufacturing is a transformative technology within the additive manufacturing family, offering unique advantages as a solid-state process. I envision this technology playing a pivotal role in emerging fields such as protective coatings, sustainable repairing, energy devices, sensor packaging, and even nuclear technology."

Dr Semik Akin

Conclusion

RPI’s adoption of the Titomic D523 exemplifies the transformative potential of cold spray technology in research, education, and industrial application. By bridging the gap between academic exploration and real-world skill development, the D523 system empowers a new generation of engineers, scientists, and tradespeople to shape the future of advanced manufacturing.

Why cold spray?

As Geert Heideman of Perron038 puts it, “I’m very excited that we have these kinds of technologies here, especially the cold spray facility, which is really unique and offers great opportunities for new products and new methods of production.”

But what makes cold spray so unique? There are a few inherent factors that allow cold spray to offer new manufacturing possibilities.

No excess heat generated

- Because cold spray doesn’t melt metals, there is no excess heat, allowing coatings to be made on existing parts with no risk of heat-related changes to the parent part or material. This is a real challenge with heat-based methods, including laser deposition and welding, as the heat can be damaging.

- Because there’s no heat, cold spray can fuse dissimilar metals that would otherwise be incompatible due to differences in melting points. This opens up opportunities for creating hybrid materials with enhanced properties, combining the strengths of different metals without the limitations imposed by traditional high-temperature processes.

A broad range of metals

- Cold spray can be used with a wide range of metals, including aluminium, copper, titanium, and more. Any metal that can be turned into a powder can be utilised, providing extensive material flexibility.

- Its applications are diverse, from repairing damaged components to creating protective coatings in industries like aerospace, automotive, electronics, and defence. This versatility makes cold spray ideal for innovative manufacturing and repair solutions.

What is cold spray?

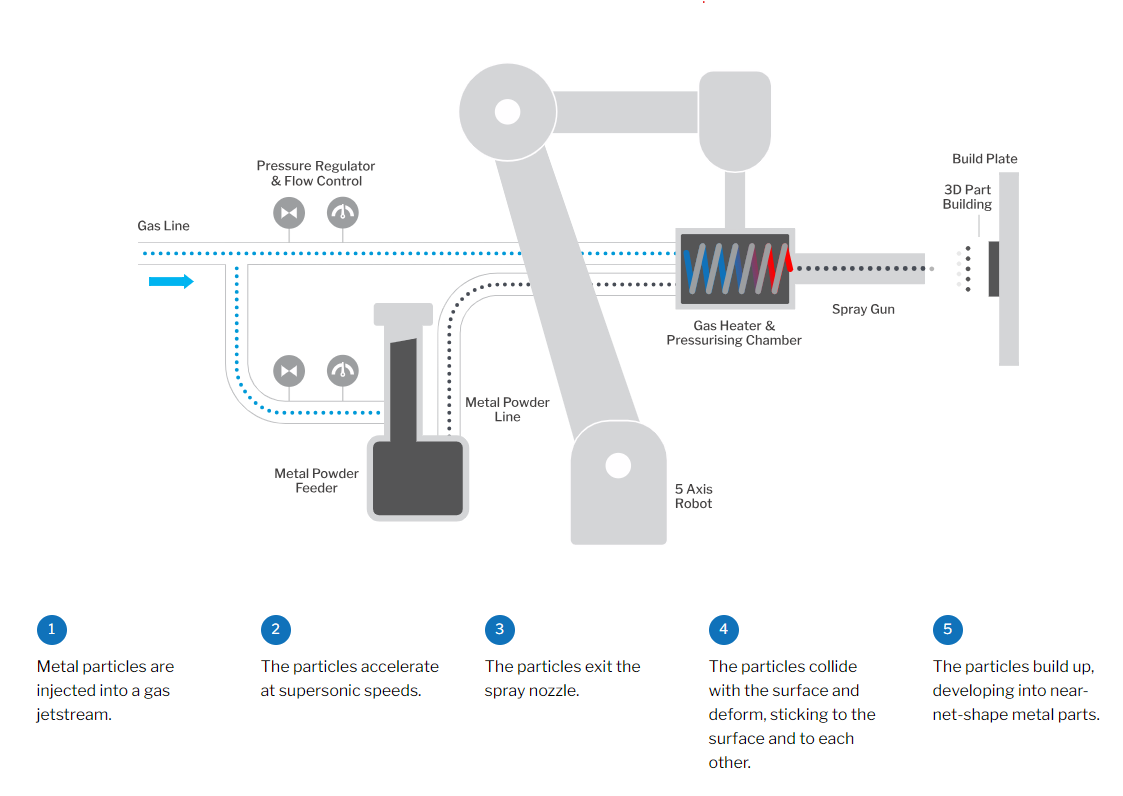

Cold spray is an advanced additive manufacturing technology that coats surfaces with strong layers of specialty metals – without ever melting them. In short, fine metal powder is acelerated to supersonic speed, and once these powders collide with the surface, they deform and mechanically bond together to form dense, strong layers of metal.

Want the full explanation on cold spray? Read further on how it works and comparisons between similar technologies.