Located in Zwolle, Netherlands, Perron038 is home to some of the most advanced manufacturing technologies available, and recently, they added cold spray to that list.

Perron038 is using Advanced Cold Spray Manufacturing to unlock new manufacturing possibilities and are delving into the material science of multi-metal coatings. With this technology, they’re providing novel solutions to industry and, in partnership with Windesheim University, educating and empowering emerging engineering students.

Why cold spray?

As Geert Heideman of Perron038 puts it, “I’m very excited that we have these kinds of technologies here, especially the cold spray facility, which is really unique and offers great opportunities for new products and new methods of production.”

But what makes cold spray so unique? There are a few inherent factors that allow cold spray to offer new manufacturing possibilities.

No excess heat generated

- Because cold spray doesn’t melt metals, there is no excess heat, allowing coatings to be made on existing parts with no risk of heat-related changes to the parent part or material. This is a real challenge with heat-based methods, including laser deposition and welding, as the heat can be damaging.

- Because there’s no heat, cold spray can fuse dissimilar metals that would otherwise be incompatible due to differences in melting points. This opens up opportunities for creating hybrid materials with enhanced properties, combining the strengths of different metals without the limitations imposed by traditional high-temperature processes.

A broad range of metals

- Cold spray can be used with a wide range of metals, including aluminium, copper, titanium, and more. Any metal that can be turned into a powder can be utilised, providing extensive material flexibility.

- Its applications are diverse, from repairing damaged components to creating protective coatings in industries like aerospace, automotive, electronics, and defence. This versatility makes cold spray ideal for innovative manufacturing and repair solutions.

"By combining the strengths of different metals without the constraints of high-temperature processes, we are opening up new possibilities for hybrid materials with superior properties."

Ferdy Touwen of Titomic Europe

Perron038 & Titomic

Leading the Netherlands in Advanced Cold Spray Manufacturing

Perron038 is embracing cold spray technology as a key part of its commitment to innovation and excellence in advanced manufacturing. By welcoming students from Windesheim University for vocational training, Perron038 is ensuring that the next generation of engineers is exposed to cutting-edge technology. These future engineers will be well-equipped to bring the benefits of cold spray to the broader industry, driving forward new applications and improvements in manufacturing processes.

As a leading company in the field, Perron038 is dedicated to undertaking extensive research and development to discover new, more effective, and efficient ways of manufacturing. Cold spray technology plays a crucial role in this endeavour, offering unique advantages such as the ability to work with a wide range of metals without generating excess heat.

"Our work in metalising resins could lead to groundbreaking applications that were previously unattainable with traditional methods."

Geert Heideman

Cold Spray Technology in Advanced Manufacturing: How Perron038 is Creating New Possibilities

Perron038 is pioneering the future of manufacturing with their focus on metalising resins and thermoplastics. By leveraging cold spray technology, they are exploring new functionalities that could revolutionise industries such as electronics and automotive, where enhanced performance and durability are paramount.

Geert Heideman emphasised the transformative potential of cold spray technology, stating, “Our work in metalising resins could lead to groundbreaking applications that were previously unattainable with traditional methods.”

In addition to their cutting-edge research and development efforts, Perron038 is committed to education and innovation. By welcoming students from Windesheim University for vocational training, Perron038 ensures that the next generation of engineers is exposed to the latest advancements in technology. These future engineers will be well-equipped to bring the benefits of cold spray to the broader industry, driving forward new applications and improvements in manufacturing processes.

Ferdy Touwen of Titomic Europe added, “By combining the strengths of different metals without the constraints of high-temperature processes, we are opening up new possibilities for hybrid materials with superior properties.” This forward-thinking approach underscores Perron038’s commitment to not only improving existing manufacturing techniques but also pioneering new ones that push the boundaries of what’s possible.

In this ambitious endeavour, Titomic stands as a crucial partner, supporting innovative and progressive companies like Perron038. Titomic’s role is pivotal in empowering innovators who dare to explore uncharted territories in material science and advanced manufacturing. For those bold enough to redefine the future of industry, Titomic is the partner of choice, championing the relentless pursuit of excellence and innovation.

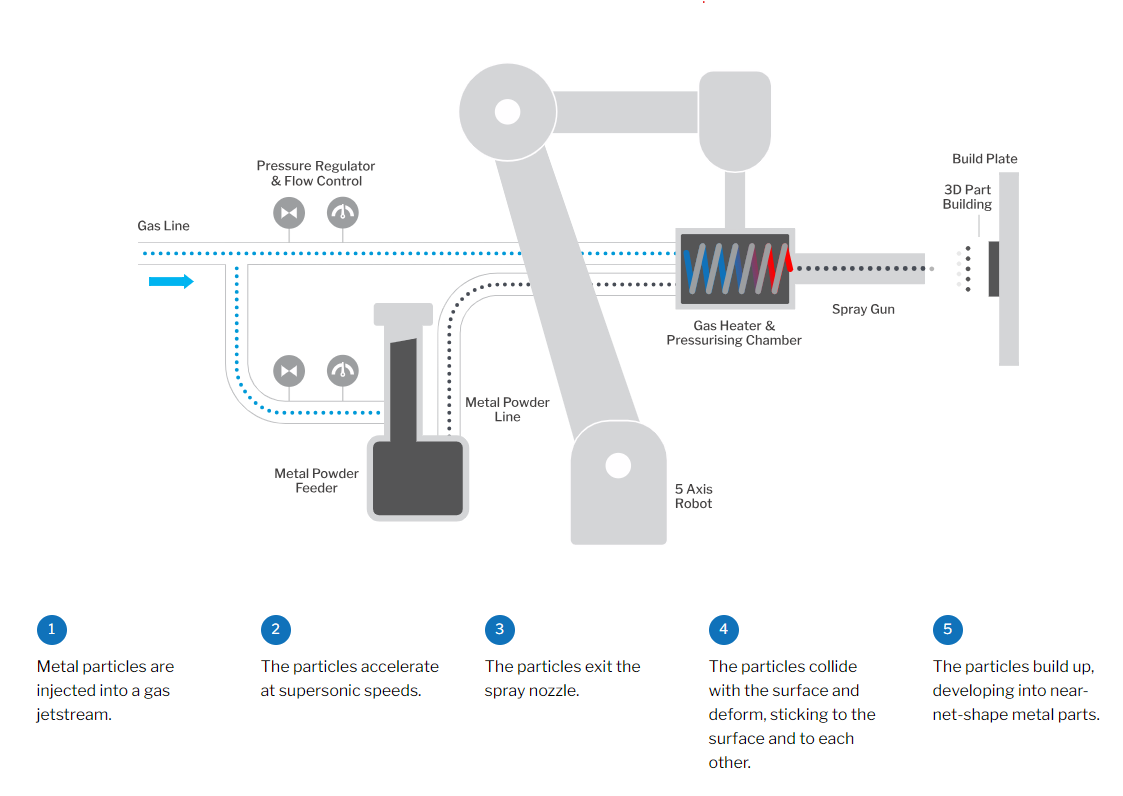

What is cold spray?

Cold spray is an advanced additive manufacturing technology that coats surfaces with strong layers of specialty metals – without ever melting them. In short, fine metal powder is acelerated to supersonic speed, and once these powders collide with the surface, they deform and mechanically bond together to form dense, strong layers of metal.

Want the full explanation on cold spray? Read further on how it works and comparisons between similar technologies.

Ready to innovate with cold spray?

To find out more about Perron038 and their capabilities, or if you’re interested in engaging them in a manufacturing project, visit their website via the link below.

Perron038 – The place to be for the innovative manufacturing industry in Zwolle