Our advanced cold spray and high-performance titanium additive manufacturing solutions deliver cost-effective, scalable solutions for critical military applications in the Defence sector.

From the rapid creation of lightweight, durable titanium parts to in-field repairs, Titomic’s expertise in high-performance structures, corrosion and wear remediation, and functional coatings, enhances mission readiness and capability for land, sea, air, and space operations.

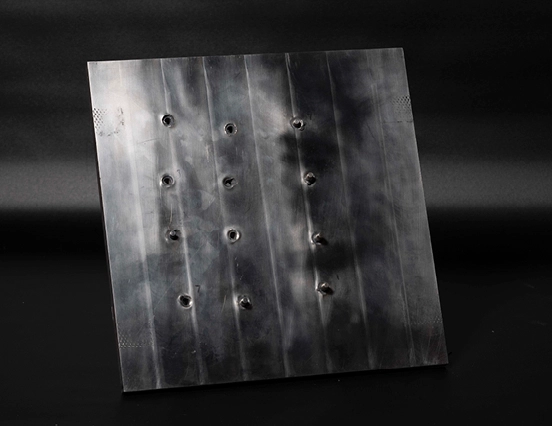

Specialising in the rapid additive manufacturing of high-performance, multi-metal components such as barrels, ballistics shielding, casings, and armour systems.

Performing secondary manufacturing operations such as adding solid metal features or thick coatings to existing parts such as flanges, ribs, and rings.

Coating and repair technologies that restore geometries and overcome corrosion and wear for large scale equipment and vehicles in demanding environments.

The ability to cost-effectively repair a wide range of parts in-situ, reducing maintenance downtime and the need to disassemble systems or parts.

Get in touch with the Titomic team for a free, no-obligation consultation today.

The diagram below gives you a quick tour of our innovative, patented Titomic Kinetic Fusion® cold spray technology. A remarkably high-speed, no-melt metal deposition method, it’s rapidly making traditional coating, manufacturing and metal part repair processes a thing of the past.

Discover how our advanced cold spray and additive manufacturing technologies are changing the world of industry.

Ideally suited to Defence sector requirements, Titomic’s manufacturing can achieve extremely high densities, up to 99.9% for pure Titanium parts, exceeding the density of cast metal parts. Titomic Kinetic Fusion® is also capable of creating parts that meet or exceed the strength of cast or forged parts, depending on the application.

Titomic Kinetic Fusion® is the world’s only technology capable of building seamless, one-piece structure parts from multiple metals. For example, titanium, copper, and high-carbon or alloy steels can be integrated into a single part, leveraging the strengths of each simultaneously.

The Titomic D523 Cold Spray System is designed specifically for in-field repairs in the toughest, most demanding environments. Whether it’s fixing battle damage on military vehicles, repairing leaks in field conditions, or maintaining equipment in remote locations, the D523 is a versatile and powerful solution

In the ever-evolving landscape of manufacturing, US-based Triton Systems, Inc. is pioneering…

With hundreds of useful, faster, cost-effective applications, you’re sure to have a query or two about what’s possible. If you can’t find the answer here, please don’t hesitate to contact us.

TKF costs significantly less than traditional manufacturing methods for the following reasons:

Our compact cold spray systems cost considerably less than traditional repair and resurfacing methods for the following reasons:

We’ve achieved typical density rates of 90-95% and over 99% when enhanced by post-processing.

If needed, it’s also possible to create less dense, more porous coatings for grip, abrasion, chemical processing and more through process optimisation, powder manipulation, and post-processing parameters.

Generally, you can achieve mechanical properties similar to casting and forging. While some parts may need to be processed with a heat treatment to make them more ductile, we can tailor process variables to meet your specific needs – a clear advantage compared to other methods.

It depends on what parts you need, as well as the mechanical properties the application requires. However, generally parts created with TKF will need some post-processing heat treatment.

Cold spray doesn’t require heat to melt the materials being sprayed. This is different to traditional metal spraying methods like welding or thermal spraying, which use heat to melt the material before it’s applied to a surface.

Instead, a high-pressure gas is used to accelerate tiny metal particles (which are usually less than 50 micrometres in size) to supersonic speeds. This creates heat through kinetic energy, when the particles collide with the surface of the object being sprayed.

Cold spray works by exploiting the kinetic energy of tiny metal particles. Low-to-high pressure gas is used to accelerate the particles (which are usually less than 50 micrometres in size) to supersonic speeds. These are then sprayed onto a surface where they compress and deform to create a cohesive bond.

This results in a strong, dense coating that can be used for a variety of applications – such as repairing damaged parts, improving the surface properties of a material, or creating new, complex shapes.

There are many metals that can be used in our cold spray systems. This includes aluminium, copper, nickel, titanium, stainless steel, Inconel, and more.

Since these all have different characteristics – such as strength, ductility, and resistance to corrosion – the chosen metals will depend on the application, as well as the properties needed for the final product.

Some metals may also be easier or more difficult to cold spray, depending on their melting point, ductility, and other factors.

What makes TKF so beneficial is that it can fuse dissimilar metals together. This means you can leverage the strengths of multiple metals in a single, monocoque part. For instance, you can fuse copper to titanium, nickel to cast iron, and much more.

Cold spray can be used on a variety of surfaces. This includes metals, ceramics, plastics, and composites.

The process is particularly useful for repairing worn or damaged metal parts, as it can restore the surface to its original shape and properties without causing distortion or weakening the material.

Our cold spray systems can also be used to add new features or properties to a surface, such as improved wear resistance, corrosion resistance, or thermal properties.

You can even use it to create new shapes or structures that would be difficult or impossible to achieve with traditional manufacturing methods.