Titomic’s cool contribution to SpIRIT satellite launch

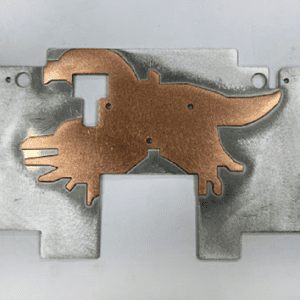

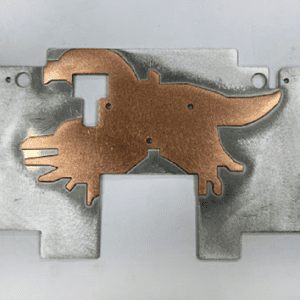

Discover how Titomic have designed a bespoke heat management system for Australia’s first scientific satellite in 20 years using cold spray.

So you can solve even the most difficult problems – or make improvements to your supply chain never before thought possible.

Our TKF AM System harnesses cold spray technology (together with software and robotics) to produce high-performance metals at unprecedented speed and scale – and with improved safety and sustainability.

Cold spray is an advanced additive manufacturing technology that coats surfaces with strong layers of specialty metals – without ever melting them.

This process unlocks limitless design possibilities with minimal heat distortion. And because the materials keep their intrinsic properties, they’re comparable or superior to cast and wrought materials.

Discover how Titomic have designed a bespoke heat management system for Australia’s first scientific satellite in 20 years using cold spray.

Titomic’s cold spray technology brings new capabilities to engine refurbishment by eliminating heat damage, reducing costs, and minimising downtime.