D523 Standard & Custom

Integrate our compact low-pressure cold spray system on-site, for on-demand metal coatings and repairs.

Overcome supply and servicing delays and improve productivity and profitability – no matter what the world brings.

Whether you’re working with metals or temperature-sensitive materials like glass, ceramics and plastics, Titomic’s fully customisable and compact cold spray systems allow you to make rapid repairs and apply metal coatings without heat – making it possible to restore parts and create denser, thicker and corrosion-resistant coatings. So you can maximise your uptime, output and productivity amidst increasingly complex challenges.

Low and medium pressure cold spray is a breakthrough technology used to coat and repair parts with softer metals, mixtures and powders – compared to high-pressure cold spray used for additive manufacturing, which applies high-strength metals and alloys.

Titomic’s cold spray systems integrate advanced powder feeders to easily and rapidly apply thinner coatings in applications across a range of industries: from aerospace to defence, energy, electronics, automotive and more.

Learn more about how our Coatings & Repairs systems can help you overcome delays, maximise uptime, and improve productivity and profitability – no matter what the world brings.

Choose your area of interest to explore our metal coating solutions:

Explore our systems for coating and repairs, or see how we can integrate a solution into your production line to solve your specific manufacturing challenges.

Integrate our compact low-pressure cold spray system on-site, for on-demand metal coatings and repairs.

Integrate our compact low-pressure cold spray system on-site, for on-demand metal coatings and repairs.

Learn what other industry leaders have achieved with our TKF Additive Manufacturing System.

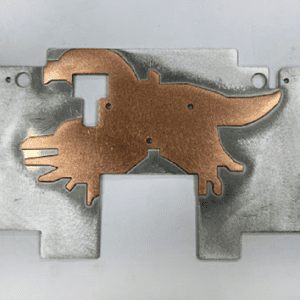

Discover how Titomic have designed a bespoke heat management system for Australia’s first scientific satellite in 20 years using cold spray.

Titomic’s cold spray technology brings new capabilities to engine refurbishment by eliminating heat damage, reducing costs, and minimising downtime.

Book a complimentary consultation to help decide if our solutions are right for you.