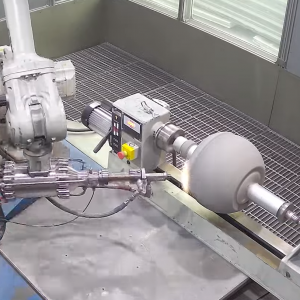

TKF1000

Go beyond 3D printing manufacturing with faster, simpler, on-demand additive manufacturing.

Put the power back in your hands, go to market faster and be more profitable with our complementary additive manufacturing systems.

From prototyping to R&D, small-run production and on-demand manufacturing, Titomic Kinetic Fusion Additive Manufacturing (TKF AM) systems bring the limitless possibilities of high-pressure cold spray technology and more to your factory floor – without making your existing equipment obsolete.

High-pressure cold spray technology makes it quicker, easier, safer and more sustainable to manufacture with metals.

This revolutionary process rapidly deposits strong metals, alloys and other specialty materials at low temperatures – so they retain their intrinsic properties without needing to be melted.

By integrating this advanced technology into our existing systems, you can produce new parts with maximum uptime.

Learn more about how our Additive Manufacturing systems can help put the power back in your hands, go to market faster, and be more profitable – without retiring your existing equipment.

Choose your area of interest to explore our additive manufacturing solutions:

Explore our systems for additive manufacturing, or see how we can integrate a solution into your production line to solve your specific manufacturing challenges.

Go beyond 3D printing manufacturing with faster, simpler, on-demand additive manufacturing.

Make the most of our versatile technology with an additive manufacturing system tailored to your production needs and challenges.

Learn what other industry leaders have achieved with our TKF Additive Manufacturing System.

Titomic’s Cold Spray Technology streamlines casting repair, ensuring fast, precise, and undistorted results for your high-stakes industrial components.

Learn how Titomic’s D523 low-pressure cold spray system was used to quickly repair a classic car with no heat. The no-heat process does what welding, putty, and epoxies couldn’t for 20 years. Now, this vintage race car is back on the track, ready to take its driver toward the podium.

Book a complimentary consultation to help decide if our solutions are right for you.