Better ballistic protection with additive manufacturing

Challenge:

With the pressure of increased threats, today’s modern combat vehicles must be lighter, more mobile and better protected than ever. And while titanium has always been an option, it’s been hampered by high costs, complex manufacturing techniques and availability.

Solution:

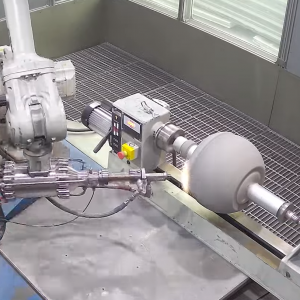

By bringing together a cost-effective and novel source of high-performance titanium with high-speed additive manufacturing technology, it’s now possible to produce larger, lighter armour at a competitive price point.

Results:

- Affordable & lightweight titanium armour

- Near-net shape manufacturing

- Weldless assembly

- Tailored performance with multi-material architectures

- More speed, range and space

- Reduced weight

Case study - US Army

The US Army is incorporating titanium armour into its existing and upcoming combat vehicles, with research citing its superior mechanical and ballistic properties.

Previous

Next