Better armaments with high-speed additive manufacturing

Challenge:

While modern weapon systems need to last longer, perform better and use more powerful propellants, barrel manufacturing hasn’t changed for hundreds of years.

Solution:

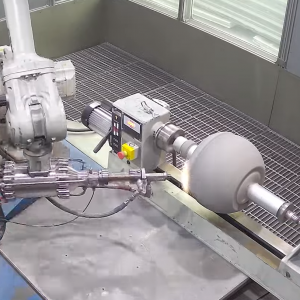

Titomic’s novel high-speed additive manufacturing process makes it possible to produce large multi-metal barrels that are lighter and offer better corrosion and erosion performance than traditional techniques.

Results:

- Faster manufacturing

- Better material combinations

- Lightweight

- Multi-metal solutions

- Better weight distribution

- Better corrosion and erosion performance

Case study - US Army

US Army researchers have taken advantage of additive manufacturing to produce weapon barrels that can withstand high temperatures during firing, reducing the logistics burden to change out prematurely worn barrels – as well as needing to supply and maintain spares.

Previous

Next