Cold spray has come a long way in recent years. Developed by Soviet scientists in the 1980s, it’s since been developed into an advanced technique for building, coating and repairing parts. So, what exactly is cold spray additive manufacturing – and how is it changing the future of manufacturing? Start with this deep dive.

Cold spray is a powerful technique for rapidly fusing powdered metals, ceramics, or polymers without melting them. It can be used to quickly repair worn or damaged components – or as a form of additive manufacturing to rapidly build parts layer by layer.

There are two types of cold spray that Titomic uses to provide a versatile range of services and capabilities:

High-pressure cold spray (HPCS): used to spray high-strength metals and alloys with compressed gases like nitrogen, helium and air at high pressures (300-1000 psi). See our high-pressure cold spray systems.

Low-pressure cold spray (LPCS): used to spray soft metals and metal/ceramic mixes with compressed gases at low pressures (below 300 psi). See our low-pressure cold spray systems.

How does cold spray additive manufacturing work?

Cold spray additive manufacturing uses a supersonic spraying nozzle to shoot a heated high-pressure carrier gas (such as air, nitrogen or helium) to accelerate particles through at high velocities.

Particles kinetically deposit onto the surface they are aimed at by interlocking mechanically and bonding metallurgically. For this reason, at Titomic we often refer to our cold spray technology suite and products as Titomic Kinetic Fusion (TKF)®.

Through this process, materials are fused below their melting temperatures (hence the name cold spray). This makes cold spray additive manufacturing superior to other methods in terms of distortion and oxidation. This also means we can build faster and thicker than other additive manufacturing technologies.

What are the benefits of cold spray?

A unique benefit of the cold spray manufacturing process is that it can be used to fuse dissimilar materials, which means we can exploit the advantages of multiple properties in a singular part.

For example, you can:

apply copper to steel for improved thermal performance

apply nickel to cast iron for repair – without distortion during welding

mix ceramics with titanium for improved wear resistance

- apply tantalum to aluminium for radiation and electromagnetic interference shielding

Other major benefits of cold spray include:

very low thermal load for working with thermally sensitive and dissimilar materials

rapid deposition rate ideal for production speeds and volumes

mechanical properties similar to highly deformed bulk material

deposition results can be in compressive residual stress for better as-built mechanical properties of many geometries

no heat affected zone (HAZ) ensures a quality bond without changing the microstructure and scaffold

no limit on deposition thickness

a ‘greener’ technology with no toxic fumes and significantly reduced waste and emissions

less reliance on the global supply chain for parts or repairs – a must during an era of shortages

extremely cost-effective compared to replacing parts

How does cold spray compare to other technologies?

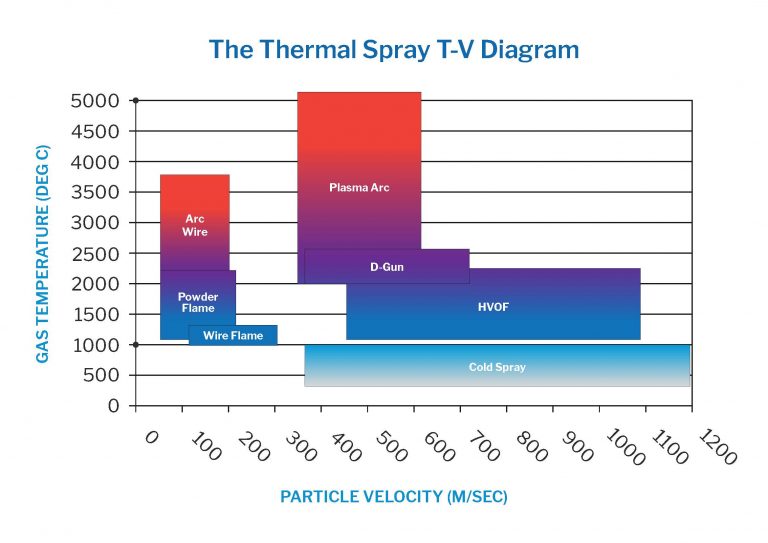

As you can see, there are many ways in which cold spray is superior to other manufacturing methods.

Whether it’s thermal spray, HVOF, plasma arc, arc wire, wire flame or powder flame, cold spray offers a significantly higher particle velocity at far lower temperatures.

High Velocity Oxygen Fuel (HVOF)

The High Velocity Oxygen Fuel coating is a thermal spray process in which a fuel and oxygen are mixed, fed into a combustion chamber, and ignited. The gas produced in the combustion chamber has an extremely high temperature and pressure and is ejected through a nozzle at supersonic speeds. This system is not portable, and uses an enormous amount of power.

Disadvantages over the Titomic TKF system:

- HVOF sprayed coatings can be extremely complex, with their properties and microstructure depending upon numerous processing variables

- Powder sizes are restricted to a range of about 5 – 60µm, with a need for narrow size distributions

- HVOF spraying requires experienced, qualified personnel to ensure safe operation and to achieve consistent coating quality

- As with all the thermal spraying processes, HVOF spraying usually needs to be undertaken in a specialised thermal spray booth, with suitable sound deadening, a water wall, and dust extraction facilities

- HVOF equipment requires more investment than other thermal spraying processes, such as flame and arc spraying

- Manual operation of an HVOF spray gun is not recommended and automated manipulation of the gun is usually needed

- Deposition of coatings is difficult or impossible to achieve on to internal surfaces of small cylindrical components.

Arc Spray

Arc spraying uses an electric arc as the heat source to melt metal wire. Compressed air (or sometimes inert gas) is used to atomise the molten metal. The electric arc is created by charging one wire positive, the other wire negative, and forcing the two wires together to create the electric arc. This system often requires huge amounts of electricity and gas. It is, however, very portable, but has minimal thickness capability, so it’s often only used for protection against corrosion.

Plasma Arc

The temperatures in a plasma flame are normally 10,000–15,000 °C. Therefore, in principle, almost any metal or ceramic including refractory metals or oxides can be melted and deposited to form a coating by plasma spraying. It is the opposite to Titomic’s Kinetic Fusion process.

Materials often overheat, leading to deformation, and become exceptionally difficult to machine, as the materials mostly need to be ground finished. Plasma arc, though, is well suited to creating hard facing and ceramic coatings on high-wear areas. The surface temperature and uniformity are critical during this process, otherwise the coating can eventually spall and cause product failure or the coating to lift off.

Take a look at this chart which compares heat and particle velocity:

What are common cold spray materials and metals?

There are many materials you can harness in cold spray additive manufacturing. These include metals like:

Titanium and titanium alloys

Invar

Aluminium and blends

Nickel blends

Copper and blends

Metal carbides

Zinc-based blends

Silver and blends

Tin-based blends

Tantalum

Gold

It’s also possible to work with high-performance alloys like AISI 4330, Ti-6AI-4V, Inconel 718 and Invar36.

See other materials we can combine to combat corrosion, wear and other issues impacting your operations.

Additive manufacturing cold spray applications:

The exciting thing about working with cold spray technology is that there are seemingly limitless possibilities. Here are a few common use for additive manufacturing:

Cylinders

Produce larger cylindrical structures and large-scale tubes optimised for strength and thermal performance with mixed material combinations. With better materials, we can improve weight, erosion and corrosion resistance.

Structures

Replace better-performing complex and costly welded assemblies with single-piece structures.

Tooling

Produce stronger, lighter, thinner and corrosion-resistant near-net shape faceplates – with reduced welding, assembly and lead times.

Ballistics protection

Produce larger, lightweight titanium armour at a competitive price point – or combine and fuse dissimilar metals to exploit the benefits of multiple metals simultaneously.

Coating & repair cold spray applications:

Wear resistance

Deposit hard-wearing metals such as titanium, steel and tungsten to enhance wear resistance on new or existing parts. Hard-wearing metals can also be fused to existing, dissimilar metal parts for repair and to enhance lifespan.

Inductive and conductive coatings

Rapidly add ferrous metals to dissimilar metal parts to harness inductive and conductive technology in cookware, manufacturing and more.

Corrosion

Use TKF to apply corrosion-resistant materials such as titanium to new or existing parts, enhancing their lifespan in corrosive environments across marine, chemical, and oil and gas applications.

Metal restoration

Use TKF systems to rapidly repair metal parts, restoring them to working order in applications across aerospace, mining, defence, boiler making and more. The systems spray metal in seconds, so you can restore parts in minutes.

When it comes to cold spray, this is just the beginning. As the cold spray additive manufacturing leaders, we’re excited to be at the forefront of this ever-emerging technology. See our case studies to discover what else is possible.

Ready to integrate cold spray into your production line? Download our design guide or book a complimentary consultation today.