Titomic has received a purchase order from TWI of GBP1.2 Million (app. A$2.28 Million at today’s rates) to supply a TKF1000 System which will be shipped in May 2022. TWI is a leading research and technology organisation in the UK, and this purchase is funded by the Aerospace Technology Institute and will form the basis of TWI’s overarching Cold Spray Additive Manufacturing Project, due to be completed before the end of 2022. The TKF1000 will allow TWI’s Industrial Members to join a portfolio of projects under the umbrella of the Cold Spray AM Project, as they develop and validate manufacturing opportunities while providing a unique competitive advantage to the UK aerospace industry.

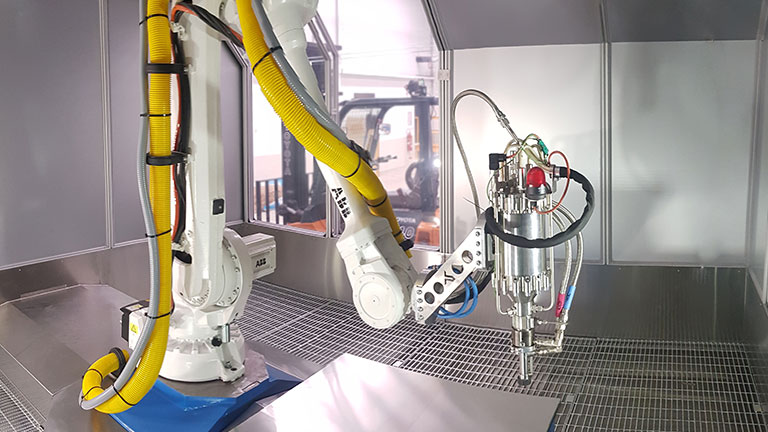

The use of the TKF System offers a number of advantages, particularly when considering fabrication from materials that are typically challenging to process by fusion-based approaches (e.g., those that suffer from oxidation, solidification cracking, anisotropic grain growth, etc.). The UK Aerospace sector will gain strategic advantage from the system’s ability to work with a wide range of metals and the potential to create large components in a short space of time, creating cost reductions, reduced lead and downtimes, and simplified supply chains are of strategic advantage to the UK aerospace sector.

Commenting on the agreement, CEO of Titomic, Mr. Herbert Koeck, stated:

“This is a significant milestone for Titomic. TWI are recognised as a leader in metals research for manufacturing applications and with their strong membership portfolio, this acquisition highlights the importance of the TKF System as a manufacturing technology. We are excited to be working with TWI and look forward to continued growth opportunities in the UK”.Commenting on the agreement, Section Manager, Dr Henry Begg, stated:

“TWI are excited to expand our cold spray capability significantly with the acquisition of the TKF1000 system. Having been active in cold spray research for the past 15 years, we will now be able to perform larger and more complex fabrications and, working closely with Titomic and our wide industrial membership base, develop the potentially revolutionary opportunities this technology brings. Complementing our existing facilities for laser, arc and electron beam additive manufacture, the TKF1000 offers a fundamentally new approach to fabrication, bypassing some of the challenges associated with solidification and opening up the possibility of multi-material builds.”